MORSTAR CUTOUT FUSE LINKS

Description

PRODUCTS INTRODUCTION

Type fuse link belong to “K” and “T” type fuse, it has general type, universal type and screw type available according to IEC-282 standard. Keyissuitable for drop-off fuse cut out with rated voltage 11-36 KV.

+ Fuse links are designed to carry 150% of their rated current without damage to the fuse link itself or the cutout in which it is installed.

+ This capacity is for special loading situations, such as short-time overloads and cold load pick-up. It has two type, type K fuse links and type T fuse links, The fast characteristics of Type K fuse links were to provide fuse links that would meet existing coordination schemes. Type T fuse links provide slower time-current characteristics than the Type K links. Type T links coordinate particularly well with automatic oil circuit recloses.

+ Materials used of Type K links

– The fusible section of the 1 through 3 ampere Type K links consist of a stainless-steel fuse strain wire; the 6 through 10 ampere, stainless-steel strain wire and a copper-alloy fuse wire; 12 through 100 amperes, a stainless steel strain wire and a silver-copper fuse wire; 140 and 200 ampere, a silver-copper fuse wire large enough to serve as both strain and fuse wire.

+ Fuse elements of Type T fuse links

1 through 3 ampere Type T fuse links employ a fusing section consisting of a stainless-steel wire serving as both strain and fuse wire; 6 through 100 ampere, a stainless-steel strain wire and a pure-tin fuse wire in parallel. 140 and 200 ampere T links have a copper element mechanically crimped at one end, soldered at the other end. On overloads or low faults, the solder becomes a fluid and the link separates; on higher fault currents, the link separates when the copper wire melts.

FEATURES

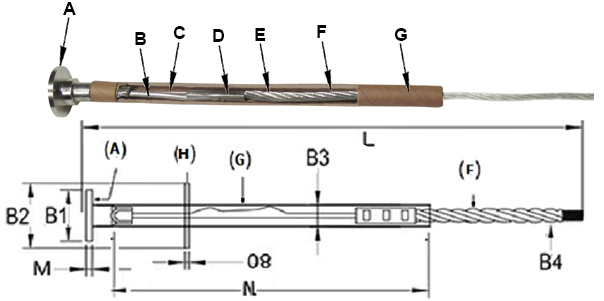

– A Removable Buttons – Allow fuse links to be used in all open and enclosed cutouts, including cutouts with arc-shortening rods.Fuse link type, ampere size and date of manufacture marked on periphery of screw terminal.

– B Fuse element: eutectic alloy which can be melted at low temperature to avoid the burning of arc-extinguishing tube.

– C High strength strain wire, which can withstand the tensile strength from fuse cutout flipper and outside pulling strength.

– D Swaged connected end guarantees the reliable connection of elements and are not easily damaged.

– E Swaged cable section prevents splaying of strands of cable, to ensure the cable’s smooth withdrawal from tube during the melting of fuse link.

– F Tinned copper stranded cable, resists corrosion, its cable diameter can resist corona.

– G Auxiliary arc-extinguishing tube, improves the capability of interrupting low fault current, and has the special ability to interrupt full range fault. Marked on length of tube to aid in identification of

fuse type K or T

– H Captive Washer – Will not fall off prior to or during installation. (Can be removed for use where 1/2″ button or no button is required.)

CHARACTERISTIC AND DIMENSION

| Rated Current Am | Dimension(mm) |

Quantity

/carton

|

||||||

| B1(mm) | B2(mm) | B3(mm) | B4(mm) | L(mm) | M(mm) | N(mm) | ||

| 1~25 | 12.5±0.2 | 19±0.3 | 6.5 | 2.0 | 580 | 2.0 | 120 | 500 |

| 30~40 | 12.5±0.2 | 19±0.3 | 8.0 | 3.0 | 580 | 2.0 | 120 | 500 |

| 50~100 | 19±0.3 | (Not applicable) | 9.8 | 5.0 | 580 | 4.0 | 140 | 250 |

| 110~200 | 19±0.3 | (Not applicable) | 12.0 | 7.0 | 580 | 4.0 | 140 | 150 |

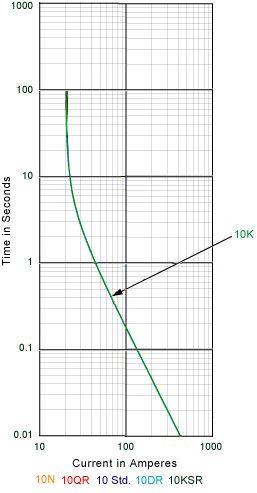

COMPARATIVE MELTING SPEED RATIO CHART

Electrical equipment such as transformers, switches, relays, and conductors are exposed to various levels of current during normal operation. Generally, electrical devices can withstand high currents for a short period of time and low current for longer periods of time without thermal or mechanical damage. The ability to withstand various levels of current for various periods of time is referred to as time-current characteristics. Coordination of power systems involves the selection of fuse links to protect equipment with various time-current characteristics while coordinating with recloses, circuit breakers, sectionalizes, relays, and other fuses. Morstar offers two types of fuse links with a wide range of time-current characteristics (refer to Table 1). The speed ratio of all fuse link sizes 100 A and below is the ratio between the current that melts the fuse in 0.1 seconds to the current that melts the fuse in 300 seconds. The higher the ratio, the slower the speed of melting. For fuses rated above 100 A, the speed ratio is between the melting currents at 0.1 second and 600 seconds.

Table 1. Speed Ratio Tin Element(s) Slow T Dual Element Designation Fast Medium Slow Very Slow Extra Slow Type K, T Speed Ratio 6-8 10-13

| Designation | Fast | Slow | Description | RATINGS & TIME-CURRENT CHARACTERISTIC (TCC) CURVES |

| Type | K | T | Type K (tube color brown) Type K fuse links have been tested to the IEEE Std C37.42™ standard requirements for a “fast” fuse. The nominal speed ratio of Type K fuse links is 7. Type K fuse links are well suited where “fast” time-current characteristics are desired such as for capacitor protection. |

|

| Speed Ratio | 6-8 | 10-13 | Type T fuse links have been tested to the IEEE Std C37.42™ standard requirements for a “slow” fuse link. The nominal speed ratio of Type T fuse links is 12. Type T fuse links provide slower time current characteristics than Types K, and coordinate well with relays and reclosers. |

FUSE LINK ORDERING INFORMATION

| 23-Inch/580mm Overall Length Rating, | ||||

| Rating, Amperes |

Rating, Amperes |

Morstar “K” Speed (TCC No. 165-6) |

Rating, Amperes |

Morstar “T” Speed (TCC No. 170-6) |

| Catalog Number* | Catalog Number* | |||

| 1 | 1K | 65101 | 1T | 65201 |

| 2 | 2K | 65102 | 2T | 65202 |

| 3 | 3K | 64103 | 3T | 64203 |

| 5 | 5K | 65105 | 5T | 65205 |

| 6 | 6K | 65106 | 6T | 65206 |

| 8 | 8K | 65108 | 8T | 65208 |

| 10 | 10K | 65110 | 10T | 65210 |

| 12 | 12K | 65112 | 12T | 65212 |

| 15 | 15K | 65115 | 15T | 65215 |

| 20 | 20K | 65120 | 20T | 65220 |

| 25 | 25K | 65125 | 25T | 65225 |

| 30 | 30K | 80130 | 30T | 80230 |

| 40 | 40K | 80140 | 40T | 80240 |

| 50 | 50K | 98150 | 50T | 98250 |

| 65 | 65K | 98165 | 65T | 98265 |

| 80 | 80K | 98180 | 80T | 98280 |

| 100 | 100K | 98100 | 100T | 98200 |

| 120 | 120K | 98120 | 120T | 98220 |

| 140 | 140K | 98114 | 140T | 98214 |

| 160 | 160K | 98116 | 160T | 98216 |

| 180 | 180K | 98118 | 180T | 98218 |

| 200 | 200K | 98122 | 200T | 98222 |