MORSTAR OVERHEAD CUTOUTS

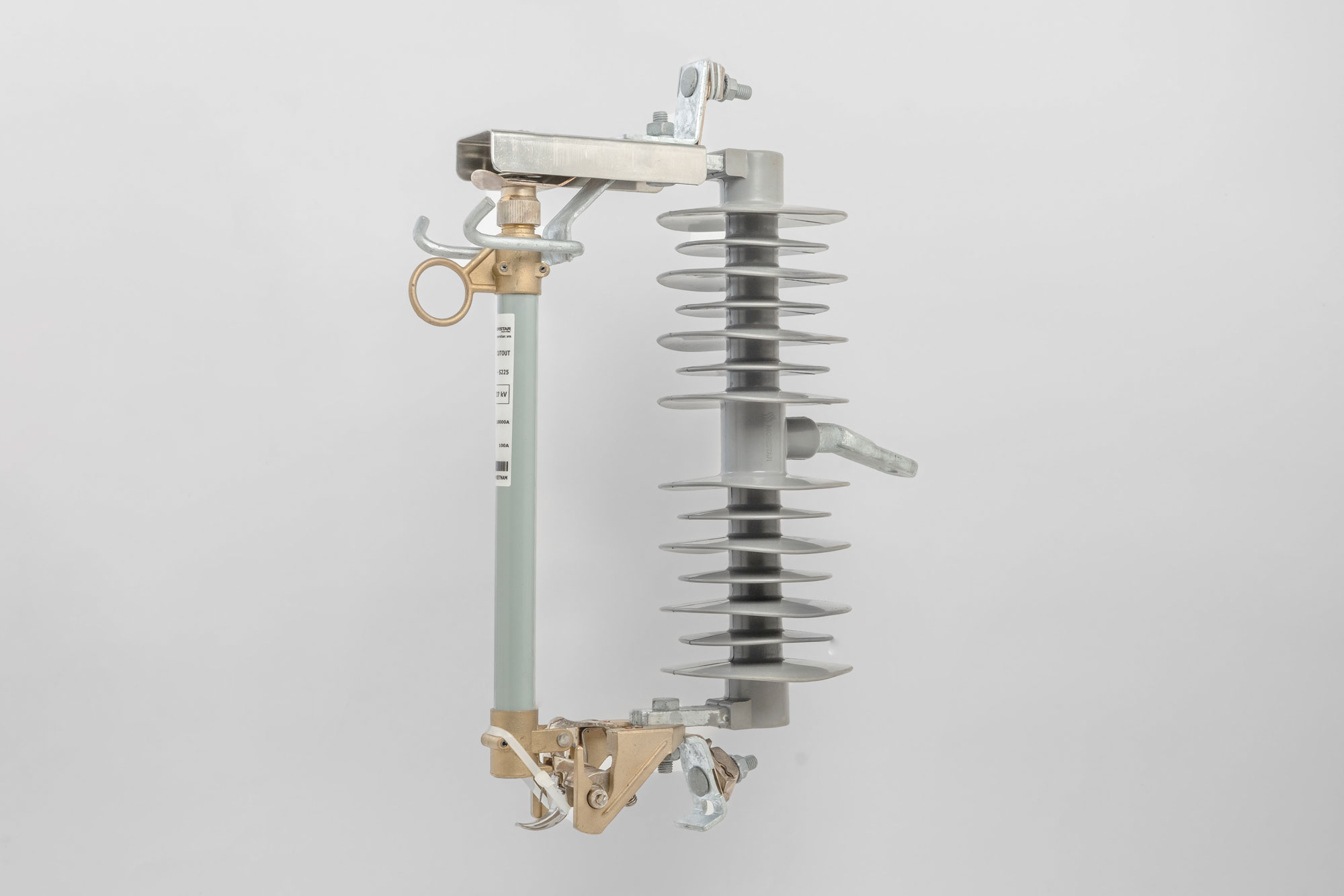

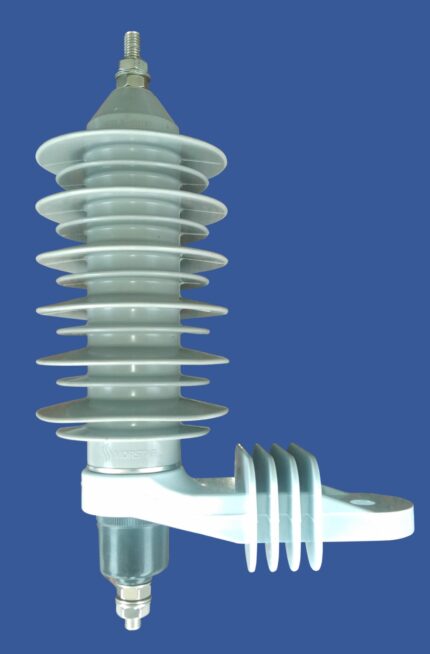

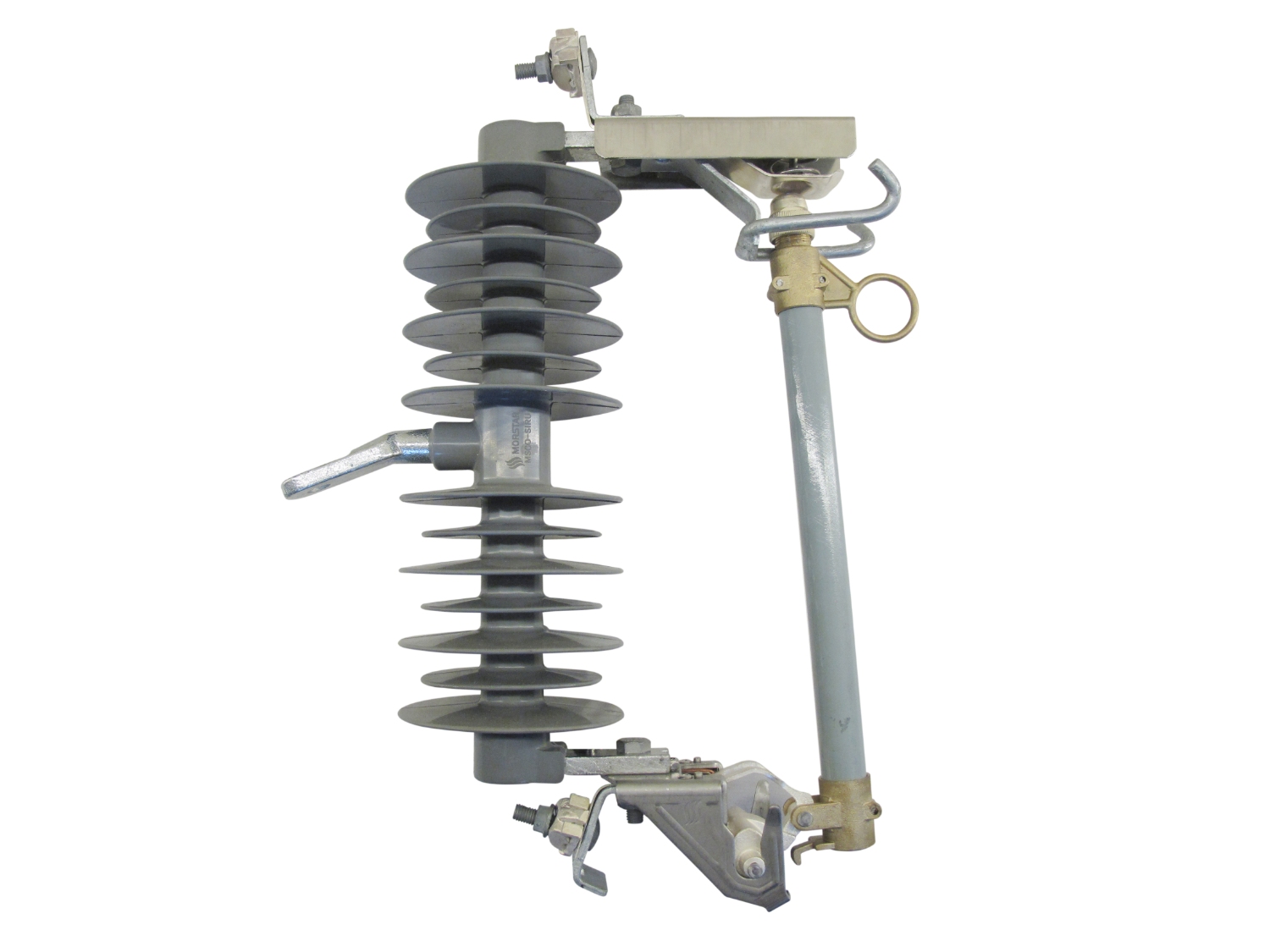

Morstar offers both porcelain and polymeric cutouts for systems rated at 15kV and 27kV, the Polymeric insulator is Silicon Rubber or HDPE for polymeric cutouts. Morstar Cutouts meet and or exceed all applicable ANSI performance requirements with testing performed at an accredited independent laboratory.

Morstar cutouts are manufactured with the following features standard: All electrical contacts are silver plated. Tin plated parallel grooves are standard. Groove 1 handles #6 solid through #6 tranded.

Groove 2 handles #2 solid through 25 mil or 4/0 ACSR. Heavy-duty galvanized sleet shield, arcing horns and NEMA Type B brackets are standard. Polymeric cutouts are manufactured out of 100% silicone rubber, not a polymer alloy. All mechanical fasteners are manufactured from 304 stainless steel.

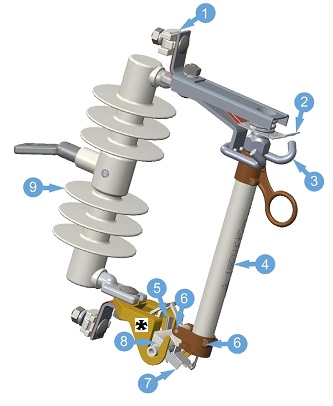

Description

- Parallel Connector – Made of tinned bronze for cables from 8 AWG to 4/0 ACSR. To ease the connection, it can accommodates two conductors with different size in a single connector. Also available in other models.

- Upper Contact – Silver to silver; stainless steel springs offers high contact pressure

- Attachment Hooks – Used as tool support for energized opening as well as to guide the fuse tube during closing.

- Fuse Tube – Vulcanized fiber covered with fiberglass and painted with a special UV resistant epoxy.

- Lower Contacts – Silver to silver; non ferrous springs offer high contact pressure

- Toggle-joint – Stainless steel construction.

- Flipper – Stainless steel construction; in conjunction with the toggle joint allows, especially during closing, the fuse link to be subject to traction forces of over 3 Kgf; it also allows for high speed fuse link separation

- Trunnion – Silver plated high strength cast bronze construction; it assists the fuse tube alignment during closing.

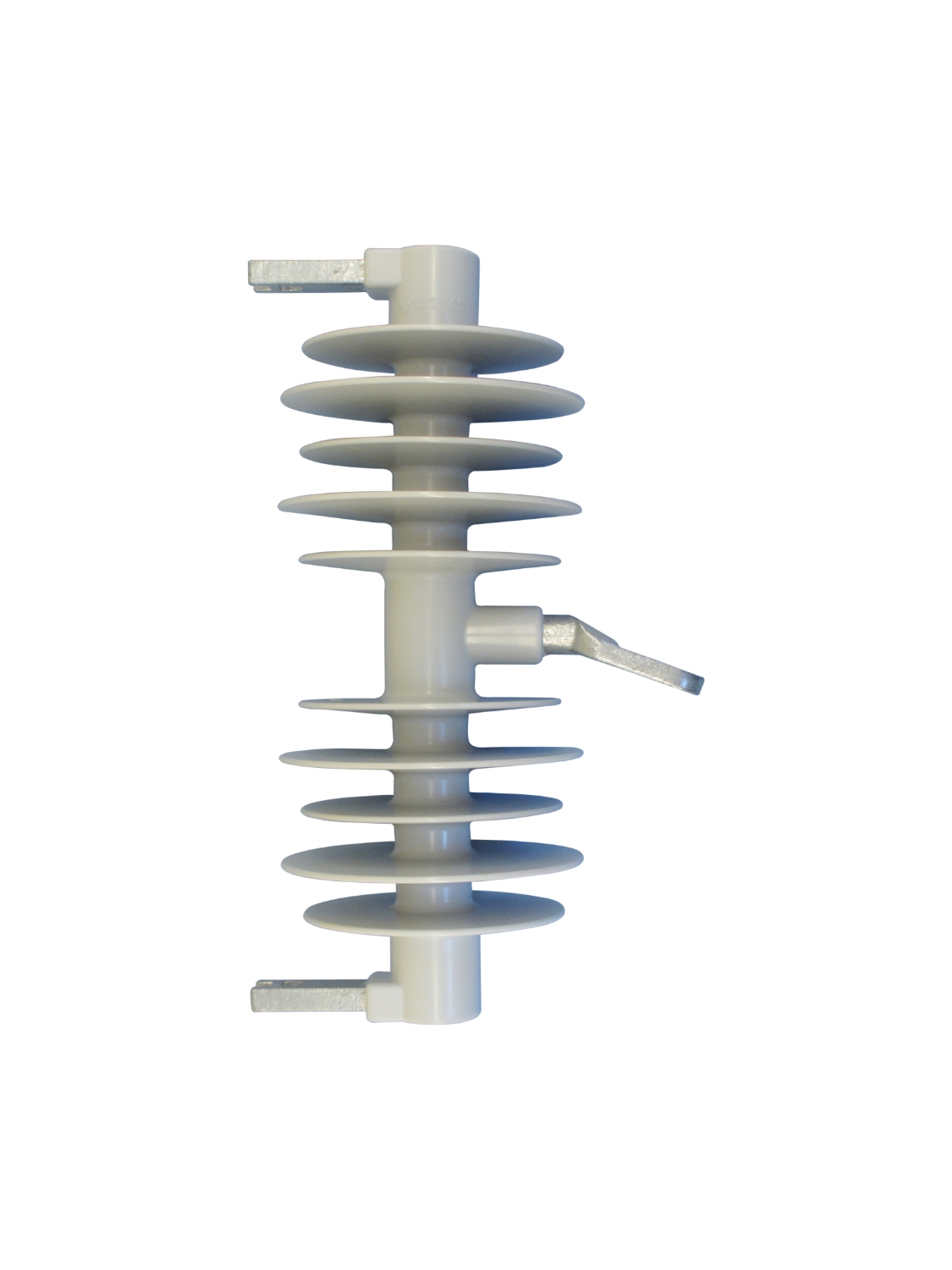

- Insulator – High strength porcelainin accordance with ANSI, IEC, or made of an ECR fiberglass core enveloped in a silicone rubber.

CHARACTERISTIC

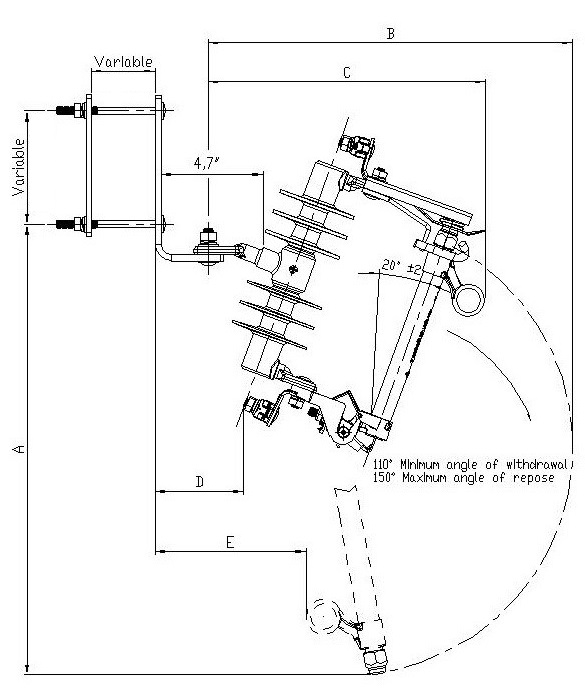

| Insulator | BiL | Dimensions in inch (mm) | ||||

| A | B | C | D | E | ||

| Porcelain and Polymeric | 110 | 21.6” (549) | 16.1”(409) | 12.9” (327) | 3.7” (93) | 5.7” (144) |

| Porcelain and Polymeric | 150 | 26.8”(682) | 18.8” (478) | 13.5” (343) | 3.1”(79) | 5.7” (144) |

| Porcelain and Polymeric | 170 | 31.9” (811) | 21.5” (547) | 14.1” (359) | 2.5” (64) | 5.7” (144) |

+The fuse cutouttype MSCO may be transformed into a DICONNECT upto 300 A, by simply changing the fuse tube for an

electrolytic copper blade. (See Figure 1)

Polymeric

| Part nbr | Voltage Rating kV | Continuous current |

Interruption level | Leakage Distance | Shipping Weight | Arc Shortening Rod | ||

| Nom. | Max. | Bil | ||||||

| MSCO-S111 | 14.4 | 15 | 110 | 100AMP | 10kA ASYM) | 15.2”-385mm | 3.165kg | No |

| MSCO-S211 | 14.4 | 15 | 110 | 200AMP | 12kA(ASYM) | 15.2”-385mm | 3.457kg | Yes |

| MSCO-S311 | 14.4 | 15 | 110 | 300AMP | 12kA(ASYM) | 15.2”-385mm | 3.675kg | Solid blade |

| MSCO-S125 | 25 | 27 | 150 | 100AMP | 12kA ASYM) | 24.4”-620mm | 3.238kg | Yes |

| MSCO-S225 | 25 | 27 | 150 | 200AMP | 10kA(ASYM) | 24.4”-620mm | 3.618kg | Yes |

| MSCO-S325 | 25 | 27 | 150 | 300AMP | 12kA(ASYM) | 24.4”-620mm | 3.936kg | Solid blade |

| MSCO-S127 | 25 | 36 | 170 | 100AMP | 12kA ASYM) | 32.6”-830mm | 6.015kg | Yes |

| MSCO-S227 | 25 | 36 | 170 | 200AMP | 10kA(ASYM) | 32.6”- 830mm | 6.330kg | Yes |

| MSCO-S327 | 25 | 36 | 170 | 300AMP | 12kA(ASYM) | 32.6”- 830mm | 6.605kg | Solid blade |

Polymeric.

| MSCO-S111 | MSCO-S211 | MSCO-S311 |

|

|

|

| MSCO-S125 | MSCO-S225 | MSCO-S325 |

|

|

|

| MSCO-S127 | MSCO-S227 | MSCO-S327 |

|

|

|