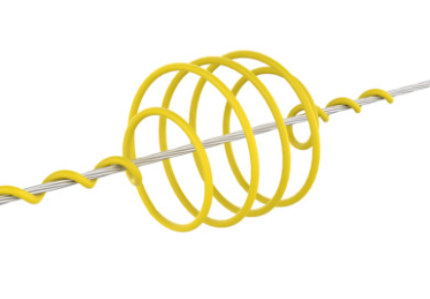

Helical products have been used for overhead power lines all over the world for over 70 years. Morstar Electric is a manufacturer, specializing in helical products and the first professional manufacturer in Vietnam, a series of helical accessories have been developed such as terminal connection, wire tying, wire splicing and wire repair. The application range of helical accessories is outstanding without tools and the supply range of these accessories is the most complete for power lines, OPGW and ADSS.

The apparent simplicity of Helical products, ease of installation on site and the electrical conductivity and mechanical ease of operation. In fact, helical products are custom designed to suit a range of conductor materials, constructions, diameters and operating conditions from coastal, icy, hot dry climates.

Description

General introduction:

Applicable standard AS115.3-1958 Section 3

Intended use: Composite porcelain head and porcelain neck ties are used to tie insulated conductors or wires on PVC pipes or pads, refer to Handbook on limiting transformers for ties.

Note: The use of porcelain head and porcelain neck Composite ties is to limit the current on the tie wire that transforms the high voltage field generated, because with the influence of a certain field transformation, the tie wire can burn and damage the wire, so the user must estimate the separate use area.

Properties: Experimental practice shows that, with unbalanced loads, the separation force from the insulator will be equal to or better than the hand tie on the covered wire.

Insulator:

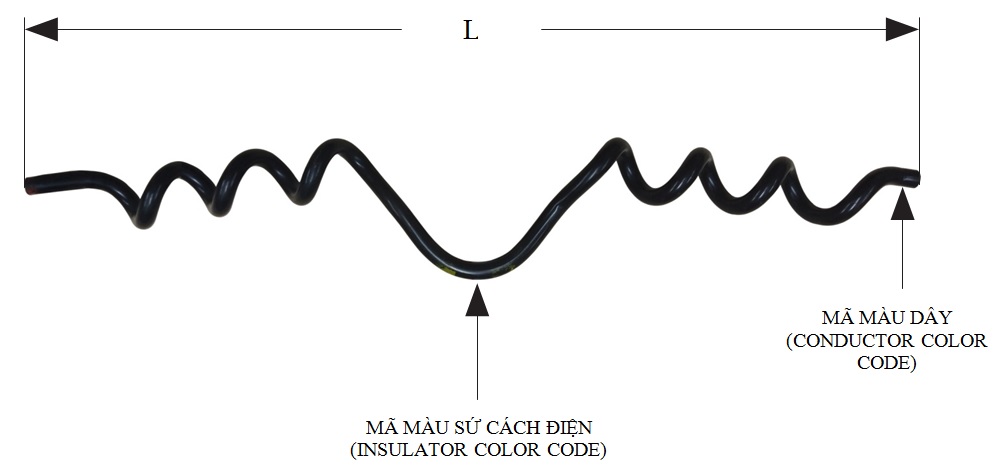

To ensure proper installation, select the corresponding porcelain neck diameters of 2-1/14” (C neck-black) and 2-7/8” (F neck-Yellow) and 3-1/2” (J neck-Green).

Material: Gray composite, resistant to impact, bending, low moisture absorption, high heat resistance, insulation and self-extinguishing properties.

Characteristic:

– Composite line tie: used to tie the wire on the porcelain head for the top porcelain and the top porcelain, applicable for straight line angles up to 15°.

– Composite Tangent side tie: used to tie wires on the porcelain neck for the top porcelain and the top porcelain, applicable for straight line angles up to 15°.

– Composite Angle side tie: used to tie the wire on the porcelain neck for the beam porcelain and the top porcelain, applicable for the line angle from 11° to 40°.

Make sure to read and understand the installation sequence before use, as well as choose the right product before use.

Important: Composite tie for insulated wire, the use of tie is affected by design, voltage, insulation and environmental conditions, the user must determine the appropriate tie for the intended use.

Testing has shown that the composite ceramic head and neck tie will develop a balanced load and wire retention equivalent to, or superior to, that of a manual tie on a shielded conductor. Unbalanced holding strength is the ability of the tie to maintain a constant and uniform hold on the conductor and insulator when continuous and uneven repetitive stress imposes an imbalance in the span. This imbalance is typically low when caused by wind-induced movement, and tree branch impact, and severe when the conductor breaks.

Safety Note:

– This product is for single use only, do not reuse or modify under any circumstances.

– This product is only applicable to trained workers. This product is not applicable to those who are unfamiliar with and have not been trained in it.

– When working in the area of live power lines, take special care to avoid electrical contact accidents.

– For proper and safe installation, individuals must ensure that the appropriate composite lanyard collar is selected before use.

To ensure proper construction, it is necessary to understand that composite tie wire is pre-shaped according to the outer diameter of the wire and the diameter of the installed porcelain neck, as well as to store it in a clean place, and to use it gently and carefully.

| Semi-Con

Plastic Morstar # |

Diameter Range (mm) | Color | Wire diameter (mm) | |

| Min | Max | |||

| AST-1013 | 10.17 | 13.72 | Brown | 11.5 |

| AST-1318 | 13.74 | 18.54 | Orange | 11.5 |

| AST-1823 | 18.57 | 23.37 | Purple | 11.5 |

| AST-2327 | 23.38 | 27.94 | Red | 11.5 |

| AST-2733 | 27.97 | 31.50(33.02) | Yellow | 11.5 |

| AST-3335 | 33.38 | 35.61(37.03) | Green | 11.5 |