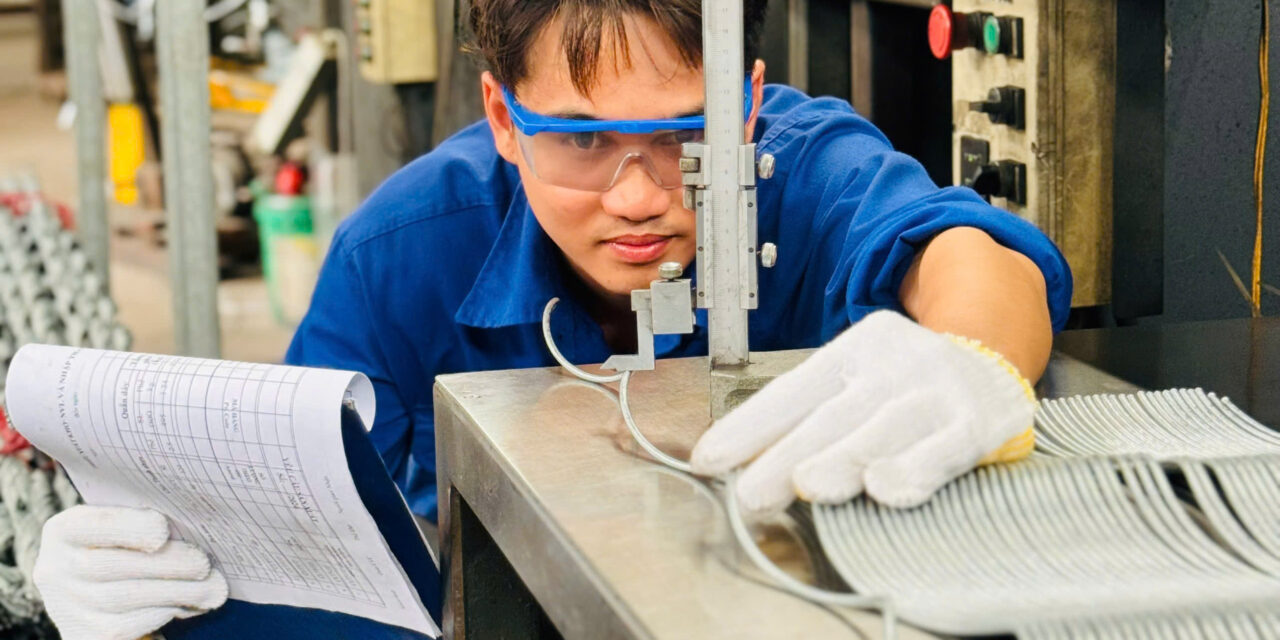

Our Processes

Fabrication perfection

The company currently uses the ISO 9001:2015 quality management system. This certificate is reviewed and re-evaluated annually, as well as regular training for the company’s staff.

Productivity – Mgm and Control, Cost-consciousness, continuous improvement

– Record of daily production with target

– Bonus for reducing wastage during production

– Recycling water for washing off the oil on the rod

– Develop auto cutting machine for crossarm

– Develop auto rod washing machine for Formed line products

– Develop auto PE coated deadend machine

–Develop auto spray painting machine for crossarm

Our management involves in daily operations intimately and interacts with employees on the shop floor regularly for better communication and encouragement.

Our management involves in daily operations intimately and interacts with employees on the shop floor regularly for better communication and encouragement.

Focus on clients

All our facilities operate under lean manufacturing and continuous improvement principles to increase efficiencies and reduce costs while maintaining the highest level of quality. Lean methods include improving workplace organization, reducing set-up times, streamlining process flows, continuous employee training, and more. Through lean, we’ve streamlined processes to ensure our clients receive the best prices, products and services in the industry.