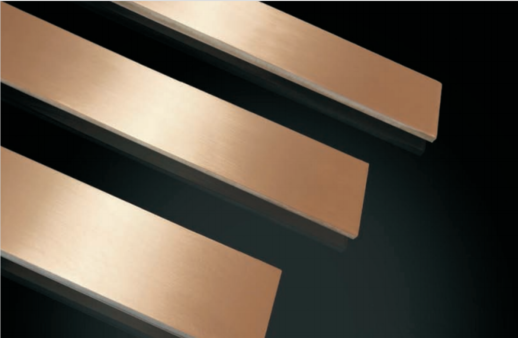

We employ a unique cast-rolling composite forming technology, which simultaneously introduces a copper strip into the liquid aluminum during its transition from liquid to solid phase. Through high temperature and pressure rolling, the atomic layers of the two metals inter-diffuse to form a crystalline bond at the interface. Subsequently, the material is cold-rolled and annealed to create a copper-aluminum composite material with a distinctive manufacturing process.

Description

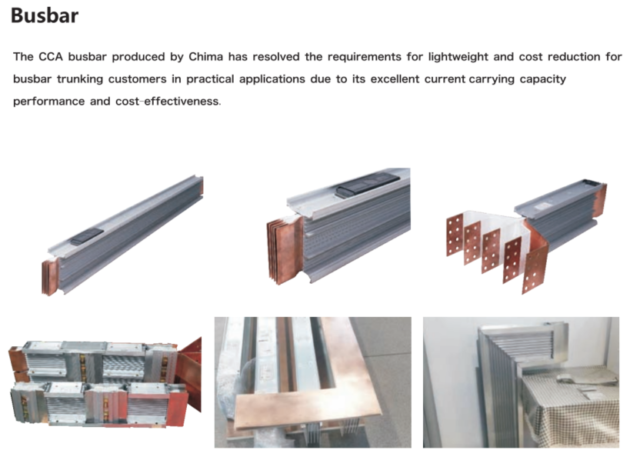

The Copper-clad-aluminum sheet is produced on basis of existing aluminum casting rolling, and it is the first of its kind both internationally and domestically. The product adopts a unique solid-liquid cast rolling technology. During the conversion process of liquid aluminum from the liquid phase to the solid phase, a solid copper plate is simultaneously introduced and rolled at high temperature and pressure, allowing the atoms at the interface of the two metals to penetrate and crystallize together, forming a unique copper- clad-aluminum sheet. Compared to copper-aluminum composite sheets produced by traditional extrusion drawing, welding, and explosive cladding methods, this product offers a revolutionary upgrade in terms of peel strength, current carrying capacity, electrical conductivity, tensile strength, and shear strength. The product can reduce the cost of pure copper consumption for users by more than 40% and be widely used in electrical engineering, electronics, photovoltaics, energy storage, military, ships, rail transit, construction, etc. It plays a significant role in alleviating the situation of China’s abundant aluminum and scarce copper, promoting the country’s “dual carbon” economy, and the national strategy for the reserve of scarce resources.

Reviews

There are no reviews yet.